Brand Name: JINKETONGLI

Model Number: ball valve

Place of Origin: Hebei, China (Mainland)

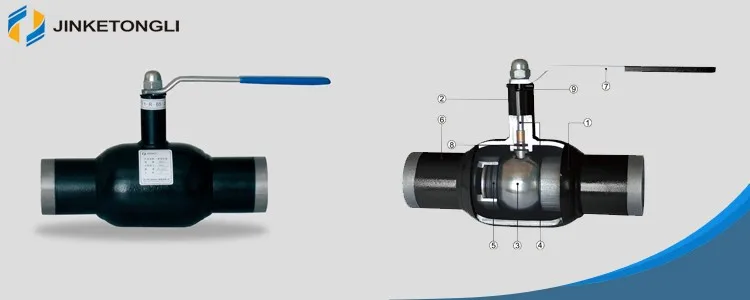

The latest steel full welded ball valve are soaring in 2015

Number |

Parts |

Material |

1 |

Valve Body |

Steel .DIN St/37.0/37.8 |

2 |

Axis Guide |

Steel .DIN St/37.0/37.8 |

3 |

Valve Ball |

Stainless Steel AISI304 |

4 |

Stem |

Stainless Steel AISI304 |

5 |

Ball Valve Seal |

Carbon reinforced PTFE |

6 |

Body Extension Tube |

Steel .DIN St/37.0/37.8 |

7 |

Handle |

Galvanized Steel |

8 |

O-ring/Stem Seal |

FPM |

9 |

Gasket |

PTEF |

JKTL fully welded ball valve conform to one or more of the following specifications for pressure, temperating ratings and dimensions: ASME/ANSI, ISO 14313/API6D, ISO 10423/API6A, ISO 14723/API 6DSS, DIN, AFNOR, British standards, ISO 9000 and API Q1.

Pressure range |

ASME/ANSI Class 150 to 2500 |

Temperature range |

-20°F to 250°F (-29°C TO 121°C) |

Body |

ASTM A350 Gr. LF-2(M) |

End connection |

ASTM A350 Gr. LF-2(M) |

Ball |

ASTM A694 Gr.F50(M) Chrome plated or ENP |

Seat ring |

AISI 1040 |

Seat load spring |

AISI 1040 |

Stem seals |

PTFE |

Lips |

PTFE |

Seat ring insert |

Nylon |

Materials used in ball valve construction are equivalent at all JKTL manufacturing plants. However, the availability of local supplies, the need to conform to national standards and to offer various trims may necessitate some variation. In corrosive applications, valve trims may be offered using various types of alloy and stainless steel. For more information on material specifications and properties, contact us directly.

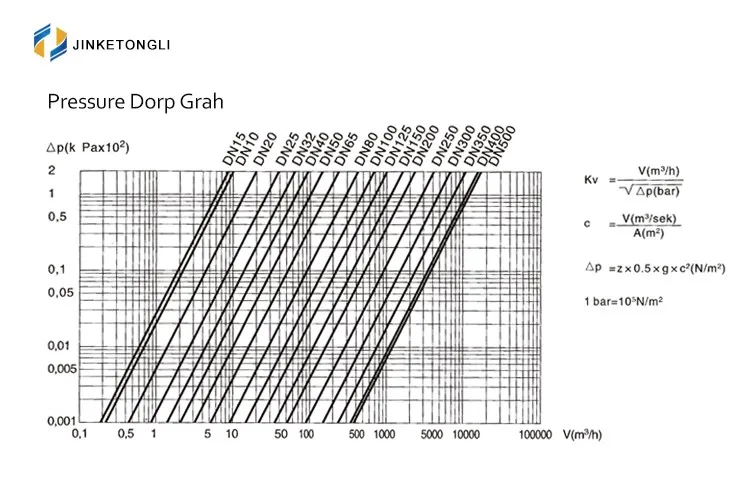

The torque stated are for guidance only, they have been obtained by measuring on new ball valve. The torque is to be understood as the pull-off torque applicable for a closed, but recently activated ball valve. The valves stated may rise to a factor of 1.5 after a long period of not being in service.

Ball valve in fully open position.

Medium: water.

Density in 1000kg/m3

KVS:

DN |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

Kv |

7 |

6 |

14 |

26 |

43 |

64 |

100 |

160 |

280 |

450 |

690 |

1100 |

1500 |

2770 |

A×10-4 |

0.79 |

0.79 |

1.77 |

3.14 |

4.9 |

8.04 |

12.56 |

19.63 |

33.18 |

50.27 |

78.54 |

122.72 |

176.71 |

314.16 |

z |

0.32 |

0.44 |

0.41 |

0.37 |

0.33 |

0.4 |

0.4 |

0.39 |

0.36 |

0.32 |

0.33 |

0.32 |

0.35 |

0.33 |

Sign explanation

Kv: m3 water per hour at pressure drop 1bar.

c: Flowrate of the media in m/sec.

V: Actual flow volume.

A: The area of flow in m2 of the ball valve in question.

z: Coeffcient of resistance.

g: Density in kg/m3

Handle |

|

DN15-DN150 |

Galvanized Steel |

DN200-DN250 |

Spraying carbon steel |

DN250-DN1400 |

No handle, using the handwheel |

We recommend DN300-DN1400 manual gearbox operation. |

|

Running Condition: |

|

temperature -30°C-+200°C(less than 0°C, contact us) |

|

Fire-Tested for Safety

JKTL fully welded ball valves can be supplied to API6FA, API607 and ISO 10497 standards. If industry standards change or customer requirements vary from the above, please contact your sales representative.

Trunnion Mounted Ball Allows Low-Torque Operation

Regardless of size or pressure rating, every JKTL fully welded ball valve is trunnion mounted. High-strength forged stems are located in PTFE impregnated stainless steel bearings for smooth, accurate operations. Trunnion mounted stems absorb the thrust from line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure, operating torque stays low.

Test Valve Integrity

When the valve body is vented, the seat seal’s integrity is verified. This test can be performed with the valve open or closed. Valve performance can also be validated by verifying valve seat seal integrity.

Features and Benefits

Upsteam Sealing

At low pressure, seat-to-ball contact is maintained by Belleville Springs. At higher pressures, seat contact is reinforced by line pressure.